Need a shock absorber for your critical application? With an easy to use interface, multiple product selection and models to include in your design, we make it easy for you to find the right product - everytime!

Deceleration of Large Equipment

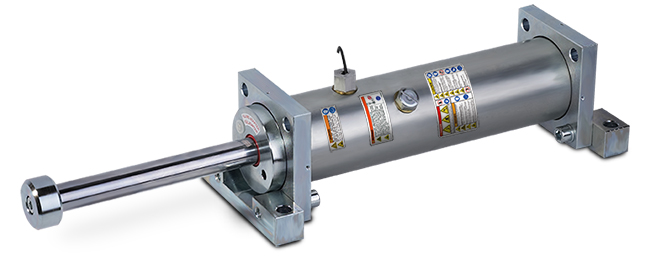

Enidine's HD/HDN Series of heavy duty shock absorbers protect equipment from large impacts in applications such as automated storage and retrieval systems as well as overhead bridge and trolley cranes. They are available in a wide variety of stroke lengths and damping characteristics to increase equipment life and meet stringent deceleration requirements.

Utilizing a special compact design, these industrial shock absorbers smoothly and safely decelerate large energy capacity loads up to 8 million in-lbs. per cycle. These HD/HDN models incorporate an internal, air charged bladder accumulator, replacing mechanical return springs, providing a shorter overall length and reduced weight. The zinc-plated external components provide enhanced corrosion protection, while epoxy painting and special rod materials are available for use in highly corrosive environments. All of Enidine's heavy duty hydraulic shock absorbers are engineered to meet OSHA, AISE, CMMA and other safety specifications such as DIN and FEM.

Enidine HD/HDN heavy duty industrial shock absorbers are offered with a wide variety of optional configurations, including bellows, clevis mounts and safety cables. Standard adjustable or custom-orificed non-adjustable models are also available as well as optional fluids and seal packages to expand standard operating temperature range from (15º F to 140º F) to (-40º F to 210º F). For easy maintenance, all sizes of Enidine heavy duty hydraulic shock absorbers are fully field-repairable. These products also offer piston rod extension sensor systems for reuse safety requirements.